Intro to Plants

Aromatic Plant 1

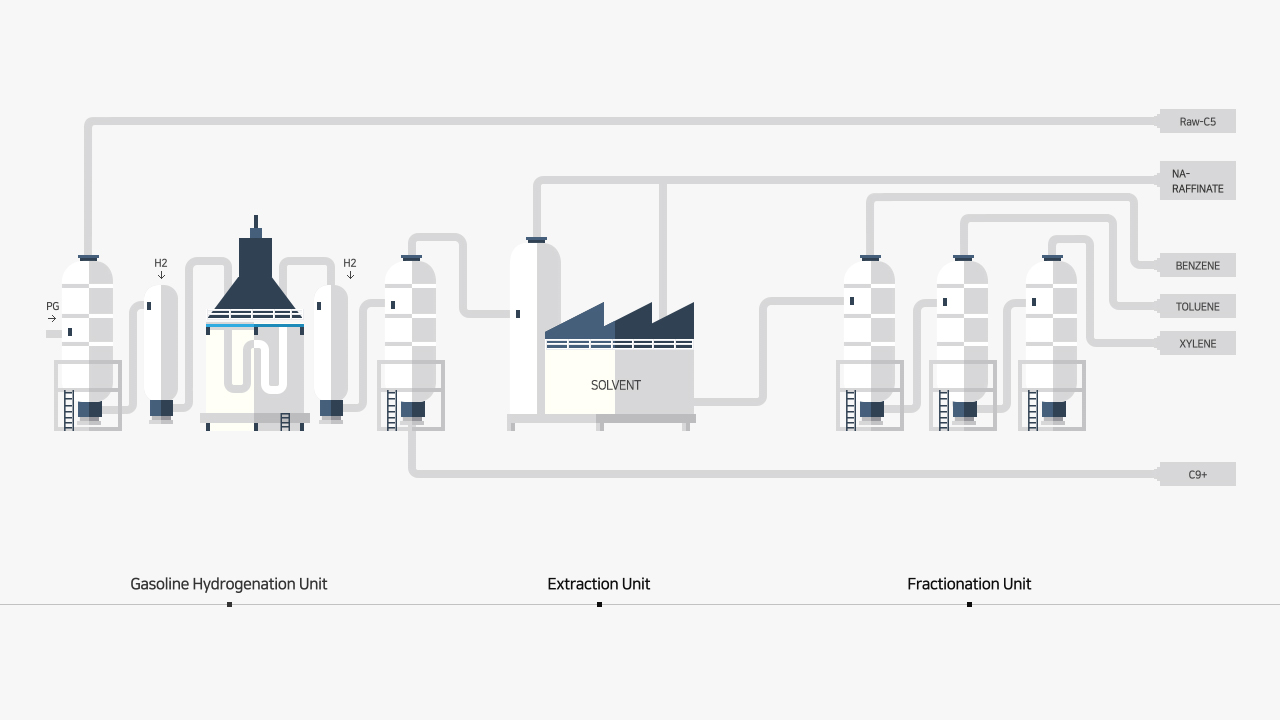

Aromatic plant 1 started commercial operation in April 1980 with the introduction of Lummus and UOP technology. pyrolysis gasoline (PG) is used as a raw material, and the aromatic solvent is selectively extracted by hydrotreating and using sulfolane, which is an extraction solvent, and is produced by separating from high-purity benzene, toluene and xylene.

-

- Gasoline Hydrogenation Unit

- To produce high-purity products, this unit hydrogenates the double-bond compounds in the high-purity feedstock to make saturated compounds, and removes sulfur compounds and turn them into feedstock suitable for the extraction unit.

It sends the hydrogenated HEART CUT mixed C6~C8 to the extraction unit, and Raw-C5 is used as feedstock for the C5 plant, whereas C9+ is used as feedstock for the hydrodealkylation unit (HDA).

-

- Extraction Unit

- This unit selectively extracts aromatic compounds, among the C6~C8 mixture(HEART CUT), that dissolve well in sulfolane, an extractant. The extracted aromatic compounds are sent to the fractionation unit.

-

- Fractionation Unit

- This unit uses the difference in boiling points of aromatic mixture coming from the extraction unit and hydrodealkylation unit to produce high-purity benzene, toluene and xylene.

Product uses

| Raw-C5 | Utilized as the raw material for isoprene, DCPD and piperylene in C5 plant. |

|---|---|

| NA-RAFFINATE | Used as feedstock for the solvent. |

| BENZENE (BZ) | Used as feedstock for cyclo hexane and styrene monomer. |

| TOLUENE (TL) | Used as a solvent. |

| XYLENE (XL) | Used as feedstock for solvents and synthetic fiber. |

| C9+ | C9+ is produced from Aromatic plant and used as fuel. |