Intro to Plants

Aromatic Plant 2

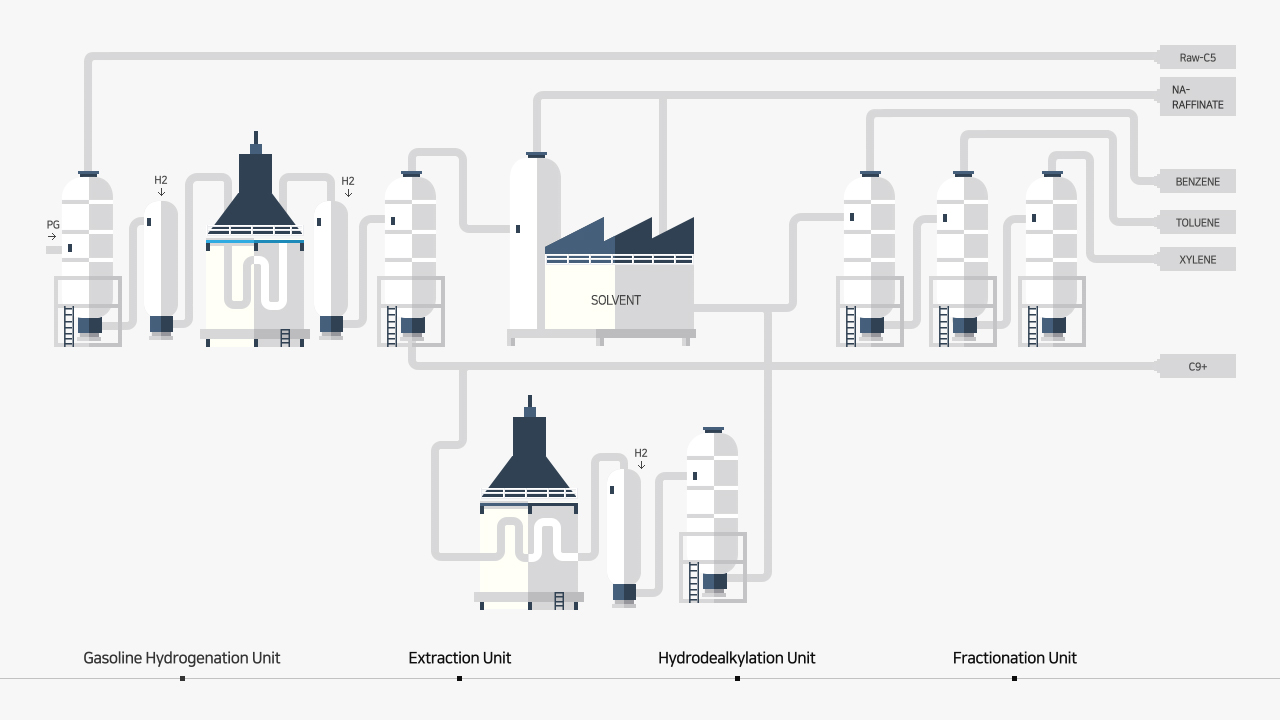

Aromatic plant 2 started commercial operation in December 1992 with the introduction of IFP and HRI technology. This plant uses pyrolysis gasoline (PG) as feedstock, and sulfolane, the hydrogenated and extractant, to selectively fractionate aromatic raffinate, and then high-purity benzene, toluene and xylene.

-

- Gasoline Hydrogenation Unit

- To produce high-purity products, this unit hydrogenates the double-bond compounds in the high-purity feedstock to make saturated compounds, and removes sulfur compounds and turn them into feedstock suitable for the extraction unit.

It sends the hydrogenated HEART CUT mixed C6~C8 to the extraction unit, and Raw-C5 is used as feedstock for the C5 plant, whereas C9+ is used as feedstock for the hydrodealkylation unit (HDA).

-

- Extraction Unit

- This unit selectively extracts aromatic compounds, among the C6~C8 mixture(HEART CUT), that dissolve well in sulfolane, an extractant. The extracted aromatic compounds are sent to the fractionation unit.

-

- Fractionation Unit

- This unit uses the difference in boiling points of aromatic mixture coming from the extraction unit and hydrodealkylation unit to produce high-purity benzene, toluene and xylene.

-

- Hydrodealkylation Unit

- This unit turns the C9+ mixture fractionated in the hydrogenation unit into aromatic mixture containing lots of benzene through hydrocracking and hydrodealkylation. This aromatic mixture containing a lot of benzene is sent to the fractionation unit.

Product uses

| Raw-C5 | Utilized as the raw material for isoprene, DCPD and piperylene in C5 plant. |

|---|---|

| NA-RAFFINATE | Used as feedstock for the solvent. |

| BENZENE (BZ) | Used as feedstock for cyclo hexane and styrene monomer. |

| TOLUENE (TL) | Used as a solvent. |

| XYLENE (XL) | Used as feedstock for solvents and synthetic fiber. |

| C9+ | C9+ is produced from Aromatic plant and used as fuel. |