Intro to Plants

Ethylene Plant 2

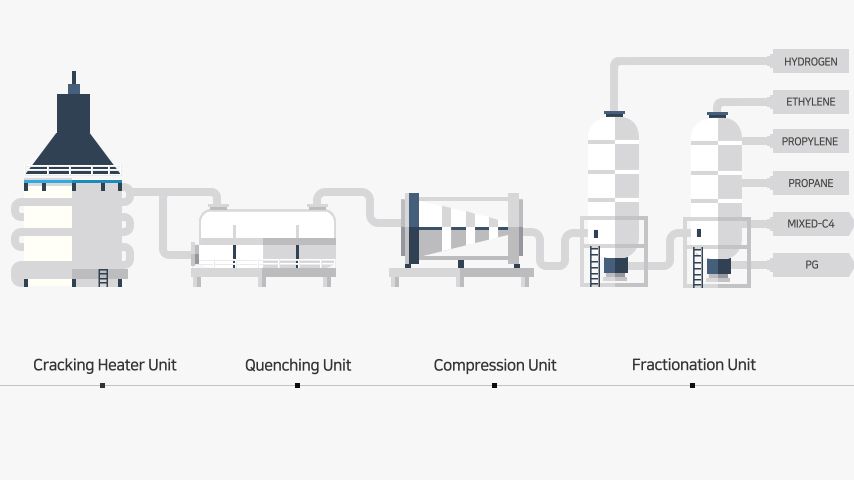

Ethylene plant 2 started commercial operation in December 1992 with the introduction of Stone&Webster technology. This plant cracking naphtha with steam into the light hydrocarbon compound at a high temperature in excess of 800℃, and quenches, compresses and fractionate it to produce ethylene, propylene, mixed C4, pyrolysis gasoline (PG), etc.

-

- Cracking Heater Unit

- This unit cracking naphtha with steam in a cracking furnace into the hydrocarbon compound with less carbon at a high temperature in excess of 800℃, produces high-pressure steam with the heat of the high-temperature cracked gas and sends it to the quenching unit.

-

- Quenching Unit

- This unit cools down the high-temperature cracked gas from the cracking furnace with quench oil, fractionates heavy fuel oil (PFO, PGO), and cools it down with quench water. the quenched substance is sent to the compression unit.

-

- Compression Unit

- To economically fractionate and refine the quenched cracked gas, this unit uses the compressor to raise the pressure to about 38 kg/㎠G.

-

- Fractionation Unit

- This unit cools down the gas compressed by high pressure at a super-low temperature (-165℃), and uses the differences in boiling points to fractionate hydrogen, ethylene , propylene , propane, mixed C4 and pyrolysis gasoline (PG), etc.

Product uses

| Hydrogen | Used as feedstock for the hydrogenation reactor. |

|---|---|

| Ethylene | It is the most important basic feedstock in petrochemistry. It is used as feedstock for High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE), ethyl alcohol, ethylene glycol, etc. |

| Propylene | Used as feedstock for polypropylene (PP), acetone, isopropyl alcohol, propylene glycol, etc. |

| Propane | Used as fuel or as feedstock for the resin plant (HDPE, LDPE, LLDPE). |

| Mixed C4 | Used as feedstock for the BD plant. |

| Pyrolysis Gasoline (PG) | Used as feedstock for the aromatic plant. |

| Heavy Fuel Oil (PGO, PFO) |

Used as fuel |